Table of Contents

WHAT IS BANANA SILK RUG

What Is Banana Silk Rug?

Banana silk rugs and carpets are those fiber rugs and carpets wherein the silk is driven from the harvesting and processing of the stems of banana plants. Banana silk fiber rugs are soft, shiny, and eco-friendly suitable for average foot traffic spaces.

Are you familiar with banana silk rugs? When thinking about the fibers used in carpets’ production, most assume that there are only two categories: the natural ones, such as wool, cotton, or silk, and the completely artificial ones, synthesized from petrochemical products, such as polyester and nylon.

Banana Silk Rug History

Give a thought, and let’s see what comes to mind when seeing banana silk rugs; well, the first thing that comes to mind is its thread. What are the essential benefits of banana plants, you know? A few you knew and one you will know now. Yes, we benefit from banana plants for their tasty nutrient-rich fruits and the large leaves used as food plates in south India.

It will surprise you to know the other unheard benefit: the silk fiber obtained from them. People have used this thread for centuries. It served as the basis for high-quality textiles. The techniques for manufacturing banana silk differ in various parts of the globe. Today, there are also forms of mechanical production. Nevertheless, the most famous classical silk of them is those from Nepal and Japan.

Japanese Banana Silk Rugs

Since these people are very sharp and meticulous, making banana silk begins in the field. They take more care of the plants to secure their softness. The producers make the thread of the banana shoots by boiling them in bleach. In this way, they prepare fibers for the yarn manufacturing process.

The specific characteristics of the textile depend on the part of the sprout that producers use in production. The external layer is the most robust and is the thickest. Therefore, artisans use it for home furniture or carpets. Since the inner part is more delicate and the fiber is softer, people use it for creating Kimonos and Kamishimos.

Nepali Banana Silk Rugs

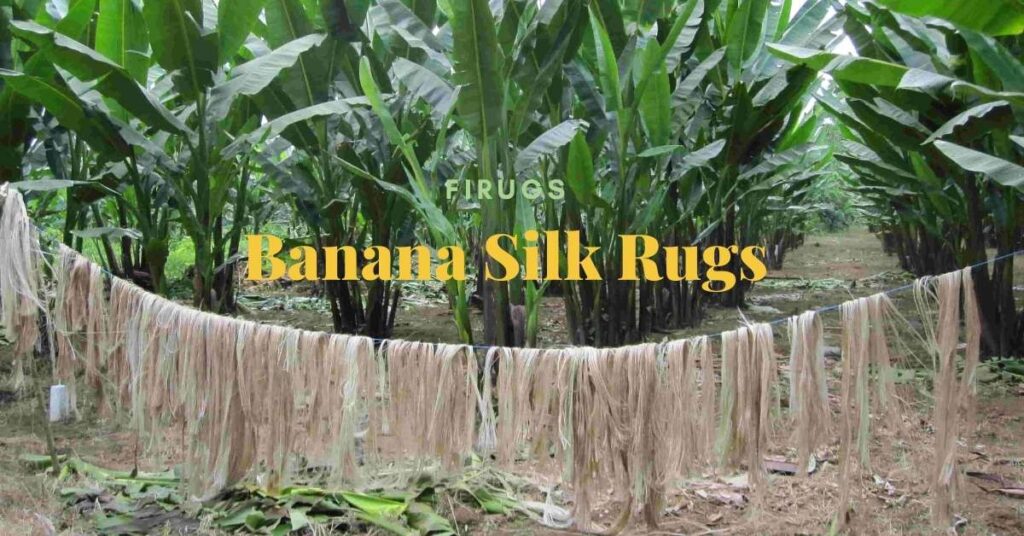

In Nepal, they follow the opposite way of extracting silk. There the banana silk producers cut the trunk of the plant instead of the shoots. They mechanically remove the fibers from pieces of logs and soften them. Subsequently, they are bleached and dried, and the thread is too similar to that of real silk, which is where the name “banana silk” came to it. Nepalese women do the refining, weaving, and dyeing. Once again, it is Nepalese women who produce them by hand.

PROs Of Banana Silk

This unique material has numerous benefits. Banana silk is rapidly gaining worldwide acknowledgment for being amazingly versatile. The fiber silk of the banana is naturally luminous with a bright outer shine.

- It not only creates a charming piece of rug, but the threads are amazingly strong.

- Its fibers are excellent and have a low elongation. Banana silk rugs have a shiny and luminous pile. Also, it is relatively light.

- The thread is lightweight. It is also perfect for absorbing moisture. Captures and releases moisture quickly.

- It is considered ecological. The material is biodegradable. Also, the fabric does not have any adverse effect on the environment.

- It can also be spun using almost all spinning methods. These include open spinning, ring spinning, semi-worsted, or bast fiber spinning. Today, banana silk is gaining more and more recognition around the world.

Banana Silk Harvesting

Contrary to what many people profess today, banana silk production isn’t a new trade. Evidence suggests that the Japanese were cutting and processing the crop to extract banana silk as early as the 13th century. However, the fiber’s popularity diminished as demand for cotton and silk from India and China escalated. Therefore, the material disappeared from the general consciousness.

These days, the demand for versatile fibers and fabrics (including banana silk rugs) has increased, primarily due to its standing as an “environmentally-friendly” fiber that requires no chemical processing and uses little mechanical energy.

The Silk Extraction Process

The fiber comes from “Musa Textilis,” an inedible fruit-bearing plant, from the stems(Pseudostems) of banana plant species named “Abacá.” It takes nearly 18-24 months to grow to 12-20 feet tall with 12-30 branches each. After this point, the stems can be cut every few months, making this an excellent potential yield in terms of profit.

There are many different methods to harvest the material from the Abacá plant. A straightforward approach is following a process called “retting.” In the retting process, the stem of the stalks is dip in water to soften the material and promote the separation of individual fibers from one another. Another technique is to peel the individual strips using a sharp knife. The fibers are then organically dried and braided to make silky yarn.

There is another method for producing the fabric, known as “combing.” Furthermore, there is chemical processing too, but following the chemical process would impair its commercial value. Doing so would also remove the “green” tag it proudly bears hence would lose its demand.

Once harvested, the banana fiber it is all set to be woven into different products such as bags, rope, clothing, paper, handwoven Indian charpoy bed/bench, and of course, also the banana silk rugs.